Vacuum cleaners are cleaning machines that use suction to collect dirt, dust, and waste products from industrial processes and other kinds of debris for disposal, recycling, or reuse. Industrial vacuum cleaners are used exclusively by professionals for building maintenance and industrial workspace cleaning. Read More…

We are vacuum experts, both for vacuum cleaners and vacuum systems for manufacturing needs. We will create custom systems that will help you reach your industry goals- no matter what they our.

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

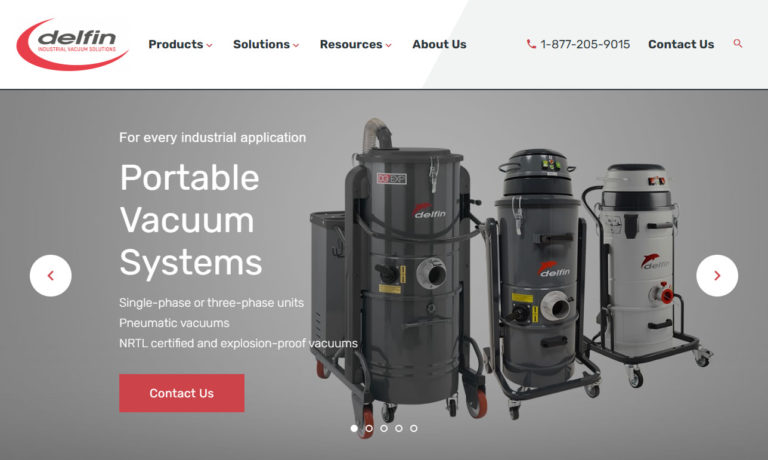

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

At Legends Equipment Company, we take pride in our custom-engineered central vacuum systems designed for heavy-duty industrial applications. Our vacuum cleaners are a testament to our commitment to excellence in providing efficient and powerful solutions for challenging environments. With a focus on innovation and reliability, we understand the unique demands of industrial settings, and our...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

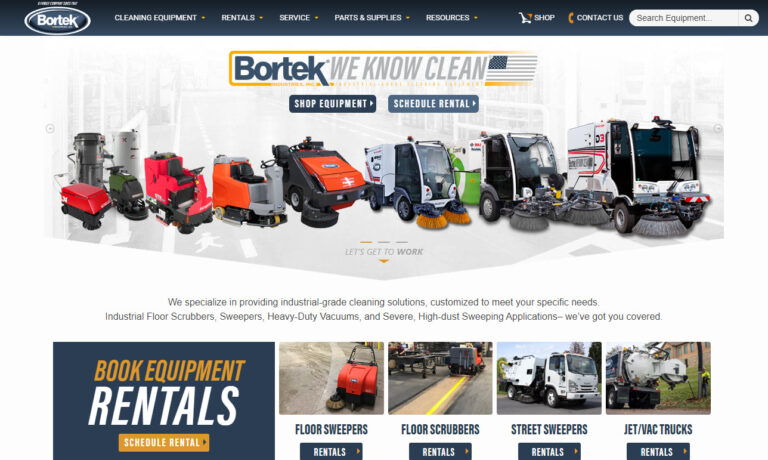

Being a world leader in the industrial vacuum arena defines Bortek. We offer litter vacuums, industrial vacuums and scrubbers, HEPA vacuums, portable vacuums and more. Our vacuum cleaners are used in industrial and commercial applications. Our industrial specialty vacuums are at your service.

Goodway Technologies Corporation specializes in industrial, commercial and wet/dry vacuum cleaners. We provide excellent customer service and support in order to help each customer choose the best industrial vacuum cleaner, vacuum cleaner system or other vacuum product to suit exacting specifications.

More Vacuum Cleaner Manufacturers

Vacuum Cleaner Applications

Industrial vacuum cleaners offer cleanup and air purifying assistance to operators in industrial applications like woodworking, metalworking, and other processes that create a constant flow of debris. They step in where commercial vacuums, which operate at lower level than industrial vacuums, just won’t cut it.

Industrial vacuum cleaners are common in a wide range of applications, including construction, commercial custodial, allergy relief and air quality improvement, industrial manufacturing, food and beverage, healthcare, furniture manufacturing, disaster relief/home reclamation, aerospace, and the automotive industry.

Vacuum Cleaner History

Industrial vacuums trace their lineage back to the earliest manual vacuum cleaners, originating in the 1860s. Daniel Hess pioneered the first vacuum cleaner, employing bellows for suction and a rotating brush, initially termed a “carpet sweeper.” Over three decades later, John S. Thurman patented the initial powered vacuum, resembling a powered broom more than today’s vacuums as it blew dust instead of suctioning it. Powered by gasoline and operated from a horse-drawn carriage due to its immense size, Thurman’s invention marked a significant advancement.

Despite their early inefficiencies and bulkiness, vacuums became commonplace in affluent households by the early 1900s. Walter Griffiths developed the first “domestic” vacuum in 1905, swiftly followed by James B. Kirby’s “Domestic Cyclone” in 1906, which garnered considerable success, leading to the establishment of the Kirby Company.

During the 1920s and 1930s, manufacturers diligently redesigned vacuums for improved practicality, aided notably by Henry Dreyfuss, an industrial designer contracted by the Hoover Company (previously Electric Suction Sweeper Company). Dreyfuss’s innovations included lightweight designs and features such as a signal for full bags. Despite these advancements, the upright vacuum didn’t gain popularity in middle-class homes until the post-World War II economic surge.

Industrial vacuums gained traction in the latter half of the 20th century as technology advanced. The advent of the wet-dry vac allowed for versatile cleaning of both wet and dry areas, enhancing efficiency in handling large spills and dirty environments. Over time, industrial vacuums diversified and improved, with today’s market thriving on innovations focused on efficiency, sustainability, ease of use, and enhanced suction power envisioned by design engineers for future models.

How Vacuum Cleaners Work

Vacuum cleaners can be adapted to handle a wide range of materials, including fine powders, abrasives, explosive substances, litter, non-free flowing materials, metalworking chips, hazardous substances, pet hair, coolant, oil mist, and welding fumes. Their design varies accordingly; for instance, a vacuum intended for wood chips differs significantly from one used for liquid waste.

Types of Vacuum Cleaners

Commercial vacuum cleaners serve similar purposes but are generally less efficient and not suited for heavy-duty cleaning tasks. They are often chosen for their affordability and effectiveness in lighter cleaning applications.

Small and portable vacuum cleaners can be adapted for industrial use but are primarily used in commercial environments for less demanding tasks.

Canister vacuums exemplify portable models, featuring lightweight construction typically made from stainless steel or plastic, ensuring easy portability.

Continuous duty vacuums are designed for uninterrupted 24/7 operation, crucial in environments where hazardous debris is regularly generated. In such settings, explosion-proof vacuums may be necessary to minimize fire risks.

HEPA vacuums cleaners, equipped with high-efficiency particulate air filters, are crucial in industrial settings, including manufacturing floors and the food industry. They effectively capture even the smallest particles, enhancing air quality during cleaning operations.

Auto vacuums, some of which are wet-dry cleaners, are specialized for vehicle cleaning. Often found at car washes, they feature high-capacity dust containers and removable attachments like crevice tools, catering to interior cleaning needs.

Central vacuum systems facilitate debris collection throughout buildings via built-in ductwork, with motor and filtration systems typically located near the ducts. They are prevalent in building maintenance and select industrial applications.

Explosion-proof vacuums are specifically designed to handle potentially explosive materials such as combustible dust or flammable liquids safely.

Rechargeable vacuum cleaners offer cordless convenience, ideal for portability and ease of use. They are rechargeable beforehand, eliminating the need for constant power outlets, and often feature HEPA filters for improved air quality, beneficial for asthma and allergy sufferers.

Vacuum Cleaner Equipment Components

Industrial vacuums vary in complexity, often featuring numerous components. Apart from the filter, these vacuums typically incorporate stainless steel or plastic parts. Key components include air pumps, hoses, brushes, controls (including switches and remote controls), power sources, filters, and a dirt receptacle.

Air pumps, such as centrifugal fans, generate the necessary partial vacuum for debris suction. Hoses serve as crucial connectors, enabling users to extend their cleaning range. Brushes facilitate cleaning in challenging, inaccessible areas.

Benefits of Vacuum Cleaners

Vacuum cleaners serve as ideal industrial cleaning tools for numerous reasons. Firstly, they efficiently gather both liquid and solid industrial waste without causing damage, allowing for potential reuse of materials. Specialized filters can also be employed to prevent unintended collection of dust or dirt, ensuring precision in waste management. Once collected, materials can be cleaned and readied for future processing.

Secondly, unlike sweepers, vacuums operate without stirring up dust, which can pose health risks in certain environments. They require minimal labor, offering a practical advantage. Additionally, vacuum cleaners can be equipped with HEPA filters, particularly beneficial in settings generating substantial waste or dust. These filters effectively capture both large particles and fine particulates, thereby enhancing the quality of workspace air.

Vacuum Cleaner Design and Customization

When designing an industrial vacuum system, manufacturers carefully consider several crucial design elements: the power source, filter material, dirt storage method, and airflow configuration. Let’s explore each aspect in more detail.

Power Source: Manufacturers must choose between centralized power, plug-in operation, or battery power, depending on the need for portability.

Filter Material: The selection of filter material depends on the substances the vacuum will handle—solid, liquid, dust, hazardous—and the required level of filtration. Filters vary in their ability to handle dry or wet materials and particle sizes, with options like HEPA filters for fine particulates and water filters to prevent dust recirculation.

Dirt Storage Units: Designers decide on the best dirt containment system, whether it’s a reusable or disposable bag setup, or utilizing cyclonic separation.

Airflow Design: Vacuum airflow, the speed of the suctioning air stream, is critical for achieving the required suction power. Higher suction demands necessitate greater air pressure from the vacuum motor.

Vacuum Cleaner Safety and Compliance Standards

Depending on your industry and location, your vacuum cleaners will need to comply with various safety standards. For instance, in the United States, all industrial vacuum cleaners must meet OSHA (Occupational Safety and Health Administration) regulations. Moreover, vacuums intended for use in potentially explosive atmospheres must be explosion-proof.

In the European Union, vacuum cleaners intended for such environments must comply with the ATEX directive, which specifies equipment requirements for hazardous areas and outlines environmental maintenance protocols to ensure safety. European workplaces are categorized into ATEX zones based on atmospheric conditions. When using vacuum cleaners in the EU, ensure alignment with your supplier regarding ATEX zone requirements.

Beyond these safety standards, industrial vacuum cleaners must also meet industry-specific regulations. For example, sectors like food and beverage, medical, military, and agriculture have their own set of standards such as FDA, Mil-Specs, and USDA regulations. Before purchasing, it’s crucial to understand and comply with the specific standards applicable to your industry by consulting industry guidelines.

Things to Consider About Vacuum Cleaners

To select the ideal industrial vacuum cleaner for your needs, identifying the right manufacturer is crucial. We believe the manufacturers listed on this page are among the best options available. Each company listed here is renowned for its extensive experience, reliability, and commitment to high-quality products. Explore their detailed profiles provided below to gain deeper insights into their capabilities.

Before delving into the profiles, we recommend compiling a list of your specific requirements. This will not only streamline your search process but also facilitate meaningful discussions with potential suppliers. Consider aspects such as your budget, power specifications, material types for vacuuming, frequency of use, portability needs, space dimensions, standard requirements, delivery preferences, and post-delivery support expectations.

Once you have outlined your specifications, you can begin your search. Review the profiles of the vacuum manufacturers listed on this page and visit their websites for further information. Select three or four manufacturers that align with your needs and reach out to them individually. Engage in detailed discussions about your application to assess their suitability. Compare and contrast these conversations to identify the manufacturer that best meets your requirements in terms of services and capabilities. Once decided, proceed with placing your vacuum order confidently.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services